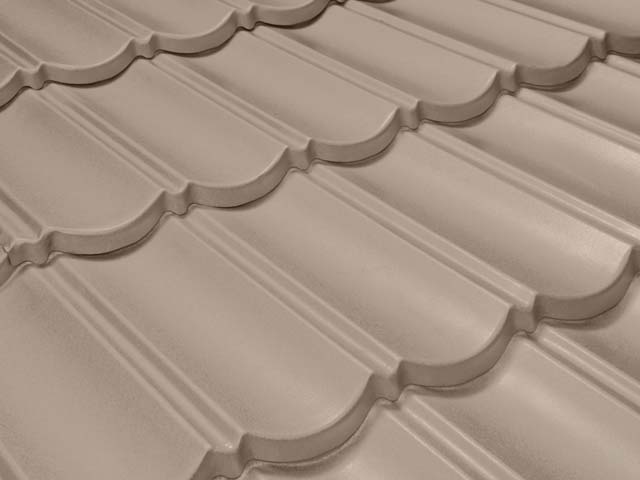

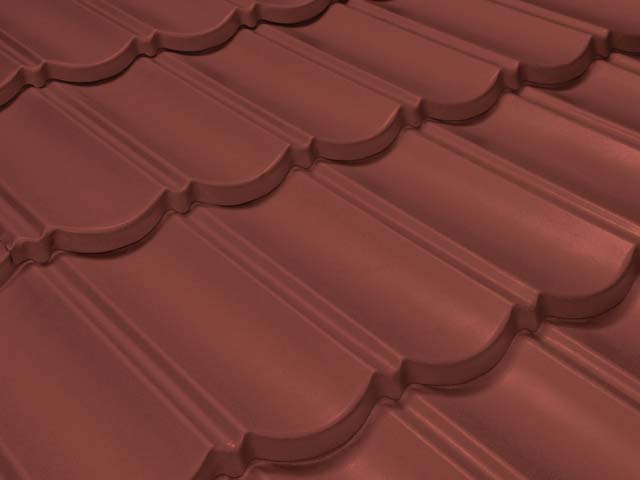

Aluminum Roofing Sheets

We deal on Aluminum long Span and steptiles roofing sheets, windows, doors and steel works, with our long span having 900mm to 1000mm (0.90m to 1.00m) effective coverage after corrugation while the steptiles ranges from 960mm to 1000mm (0.96mm to 1.00mm) effective coverage after corrugation. These are the characteristics of the product.

The overlap detail incorporates an anti-capillary drain to ensure water-tightness on a single side lap.

The broad corrugation offers a drainage capacity. The valiant appearance of the reverse side of the profile ensures use also as cladding profile.

LENGTHS

There is practically no limit to the length of sheets that can be produced. However, the maximum recommended length should not exceed 15m for 0.55mm and above while 9m for 0.45mm for handling reason.

GUAGES

The standard available gauges in Aluminum for roofing are 0.45mm, 0.55mm,0.70mm,0.90mm and 1.20mm, other non standard gauges are available on demand.

PURLIN SPACING

The following table is based on theoretical calculations and practical consideration assuming an evenly distributed load of 1.5KN/m2 or a point load of 0.9KN at mid-span and a maximum deflection of 1/200 of the span.

CONTACT OF ALUMINUM WITH OTHER MATERIALS

(i) TIMBER PURLIN

Timber preservatives that are more attuned with Aluminum (eg. Creosote or Pentachlorophenol) should be used. Timber that has been treated with a copper or mercury compound is not recommended. The certified minimum width of timber is 50mm

(ii) STEEL PURLINS

All steel surfaces in contact with Aluminum should be painted with bituminous Aluminum, zinc chromate, or other paint that does not contain lead.

In marine or industrial environments. It is advisable to provide additional installation in the form of chromate impregnated or plastic sheeting applied to the painted surface before installation. The Z purlin should face towards the ridge to allow for correct fixing of hook bolts.

(iii) ZINC COATED MATERIALS

Aluminum is not corroded by contact with zinc but in severe atmospheric conditions, the zinc may suffer attach. A coating of bituminous Aluminum should separate the contact surface between the sheers and zinc.